Overview

Supremesoft Downtime

Monitoring System (SDMS) is designed to help

plant personnel to increase plant efficiency,

identify problem production areas, locate hidden

inefficiencies of the plant, and to optimize the

maintenance intervals. SDMS provides

automated downtime tracking and efficiency data

collection functions in real time. The real time

monitoring feature of SDMS enables plant

personnel to determine the root cause of production

problems in a timely and efficient manner, and

provide immediate response to downtime events. With

the real time efficiency reports, plant personnel

will be able to analyze the Overall Equipment

Effectiveness (OEE) of the current operation and

increase the utilization of existing assets. The web

based reporting system of SDMS enables staff

from plant operation to access reports from the shop

floor, and also allows management to view

up-to-the-minute plant efficiency reports directly

on their desktop or wireless devices.

The SDMS technology is based on Supremesoft's

flagship platform (SPCS) which is

production-proven in the most demanding flexible

manufacturing environment. The design of SDMS

allows users to create downtime event definitions

without any custom programming or PLC ladder program

modifications. All the downtime events are captured

directly from the shop floor devices which

eliminates the cost of manual data collection and

improves the accuracy of the data. SDMS

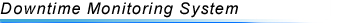

provides a rich set of web based reports for the

users to analyze and compare the effectiveness,

availability and reliability of equipment.

Key Features

- Provides true

picture of plant efficiency (OEE)

-

Automated real

time data collection directly from the shop

floor control devices (PLC)

-

Reduces the

time to determine root cause of production

problems

-

Records

downtime event accurately and eliminates manual

data collection cost !

Architecture

SDMS consists of the following main

components:

-

Downtime Manager

The Downtime Manager is the core engine

of SDMS: it continuously detects and

archives downtime events and efficiency data. It

also performs all efficiency calculations, such

as the OEE, and evaluates all the

downtime rules and conditions.

-

Report Manager

Provides a web based user interface

for the user to view and analyze downtime and

efficiency reports in real time across the

enterprise.

-

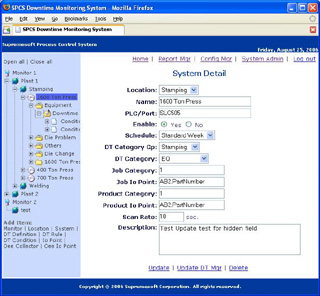

Configuration Manager

The Configuration Manager enables

users to define the logical organization of the

plant. An easy to use web interface guides users

to setup the downtime event rules and

conditions.

-

Device Manager

Device Manager is a core component of

SPCS, interfaces with all shop floor

devices thru Ethernet and serial communication.

-

Data Access Manager

Data Access Manager is a core

component of SPCS, interfaces with a

relational database management system for

downtime events and configuration storage.

The

Supremesoft Process Control System (SPCS) Foundation

The SPCS is designed to integrate the

production and enterprise environments with maximum

reliability and flexibility. The SPCS

foundation provides the middleware between the

manufacturing systems and the operating needs of the

plant: Performance Monitoring, Data Collection and

Reporting, Communications to front and Back Office,

Process and Device Control and is an Excellent

Foundation for Application Development and

Deployment.

For more information, please contact us at (905)

946-0753 or email us at

info@supremesoft.ca